rockwell hardness test symbol|rockwell hardness test calculation : bulk Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the . Resultado da 29 de jan. de 2024 · Low Latency: The app boasts low latency, which ensures that your controller inputs are registered quickly and accurately, reducing any lag or .

{plog:ftitle_list}

5 dias atrás · ADULTO +18. 23/02. 128 Visítas. Foda Boa. CarlaCute arrebentada em fodaboa com dotado. Veja [+] ADULTO +18. 23/02. 114 Visítas.

The Rockwell hardness value is made up of three main parts. These are a numeric number representing hardness, two letters “HR”, abbreviations representing “Rockwell .The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform and more accurate than other hardness methods.

Rockwell hardness (Rc) refers to a method for measuring the hardness of a material, primarily metals, using an indentation test. It is named after the Rockwell scale, which was developed .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .The Rockwell hardness number – HR, can be directly displayed on the dial. Indentation hardness measures the ability to withstand surface indentation (localized plastic deformation) and the .The Rockwell hardness values are expressed as a combination of hardness number and a scale symbol representing the indenter and the minor and major loads. For example, 64 HRC .

Rockwell hardness values are expressed as a combination of a hardness number and a scale symbol representing the indenter and the minor and major loads. The hardness number is expressed by the symbol HR and .This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests for scales A, B, C, D, E, F, G, H, K, 15N, 30N, 45N, 15T, 30T, and 45T for metallic .Table 1 — Rockwell scales Rockwell hardness scale Hardness symbol Type of indenter Preliminary test force F 0 Additional test force F 1 Total test force F Field of application (Rockwell hardness test) Aa HRA Diamond cone 98,07 N 490,3 N 588,4 N 20 HRA to 88 HRA Bb HRB Ball 1,587 5 mm 98,07 N 882,6 N 980,7 N 20 HRB to 100 HRBhardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . and penetrator to be used for your test (Table 3). Scale Symbol Typical Applications of Scales B Copper alloys, soft steels, aluminum alloys, malleable iron, etc.

The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. Therefore, a ground surface is usually sufficient, and sometimes no . (4) The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained from different scales are not comparable.

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. search. Search search close search cart. facebook . The hardness number is expressed by the symbol HR and the scale designation. There are 30 different scales. The majority of applications are covered by the Rockwell C and B scales for testing steel .Metallic materials — Rockwell hardness test — . hardness scale Hardness symbol Unit Type of indenter Preliminary force F 0 Total force F Scaling constant S Full range constant N Applicable range of application (Rockwell superficial hardness scales) 15N HR15N Diamond cone 29,42 N 147,1 N 0,001 mm 100 70 HR15N toSCOPE. The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

The Rockwell hardness test is recommended to be used on material at least 10x thicker than the indentation depth. The superficial scale uses a lighter load and can be used for thinner material. . An ohm (symbol: Ω) is the SI unit of electrical resistance, named after the German physicist Georg Simon Ohm. .The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. . The other scales also use a letter for the scale symbol prefix, and many use a different sized steel ball indenter. A properly used .the Rockwell hardness test ( scales and hardness range according to Table 1) for metallic materials. NOTE — For certain materials, the hardness range may . 4.1 The Rockwell hardness is denoted by the symbol HR preceded by the hardness value and completed by a letter indicating the scale. Examp[e: 59 HRc =

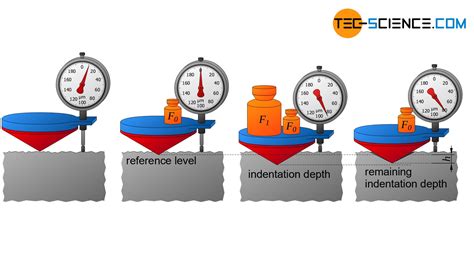

The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your right: . The hardness number is expressed by the symbol HR and the scale designation.

The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a diamond cone indenter) for harder materials and the Rockwell HRB scale (uses a ball indenter) for softer materials. . Hardness Symbol . Rockwell Hardness Scale. The Rockwell Hardness Scales comprise various types, depending on the material to be tested. Each scale utilizes different loads or indenters, and permits the testing of materials with different hardness. For instance, the HRB scale is employed for testing soft steels, aluminium, and brass, and involves applying minor .

The Rockwell hardness value is a hardness number (HR) derived from the net increase in the depth of the indentation as the force on an indenter is increased from a specified preliminary test force to a specified total test force and then returned to the preliminary test force. The Rockwell hardness number is followed by the symbol HR and the .

Correspondent relations among scale, indenter and test force: Hardness symbol Diameter of Indenter mm F/D2 Test force N/kgf HBW 10/3000 10 30 29420(3000) HBW 10/1500 10 15 14710(1500) HBW 10/1000 10 10 . Leeb rebound .ROCKWELL (S) SUPERFICIAL SCALE APPLICATIONS; Scale Symbol: Penetrator: Major (Minor) Load Typical Application: 15N: Brale: 15 kgf (3 kgf) Superficial scale is ideal for testing materials that do not have sufficient width .4 Symbols, abbreviated terms and designations. 5 Testing machine. 6 Test piece. 7 Procedure. 8 Uncertainty of the results. 9 Test report. 10 Conversions to other hardness scales or tensile strength values. . ISO 3738-1, Hardmetals — Rockwell hardness test .

Dry and wet method laser particle size Analyzer agency

The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your right: . The hardness number is expressed by the symbol HR and the scale designation. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

4 Symbols, abbreviated terms and designations . ISO 6508-2, Metallic materials — Rockwell hardness test — Part 2: Verification and calibration of testing machines and indenters ISO 6508-3, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocksMetallic materials — Rockwell hardness test — . Rockwell hardness value Rockwell hardness symbol NOTE1 Previous versions of this part of ISO6508 allowed the use of steel indenter balls, which required the suffix S. NOTE 2 For the HR30TSm and HR15TSm scales defined in Annex A, a capital S and a lower-case m is used .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . Scale Hardness symbol*1 Indenter Preliminary test force Total test force Hardness range applicable Rockwell Superficial hardness 15N HR15N Conical diamond 29.42N (3kgf)

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .Symbol: HRB : The Rockwell Hardness Test presses a steel or diamond hemisphere-conical penetrator against a test specimen and measures the resulting indentation depth as a gage of the specimen hardness. The harder the material, the higher the HR reading. In the test, a minor load (10 kgf) is first applied, and the test dial (measuring the .The Rockwell hardness (HR) is then determined from the residual indentation depth, along with a few other factors (see below). In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as .

rockwell hardness testing method

rockwell hardness tester least count

web20 de jul. de 2014 · Artist Peter Camani has created an immense, surreal artscape of huge cast-concrete sculptures throughout his 310-acre property. Locally referred to as The Screaming Heads, the property serves as the artist’s home as well as his canvas. Visitors are welcome to wander the trails that wind through meadows, past woods and ponds, to .

rockwell hardness test symbol|rockwell hardness test calculation